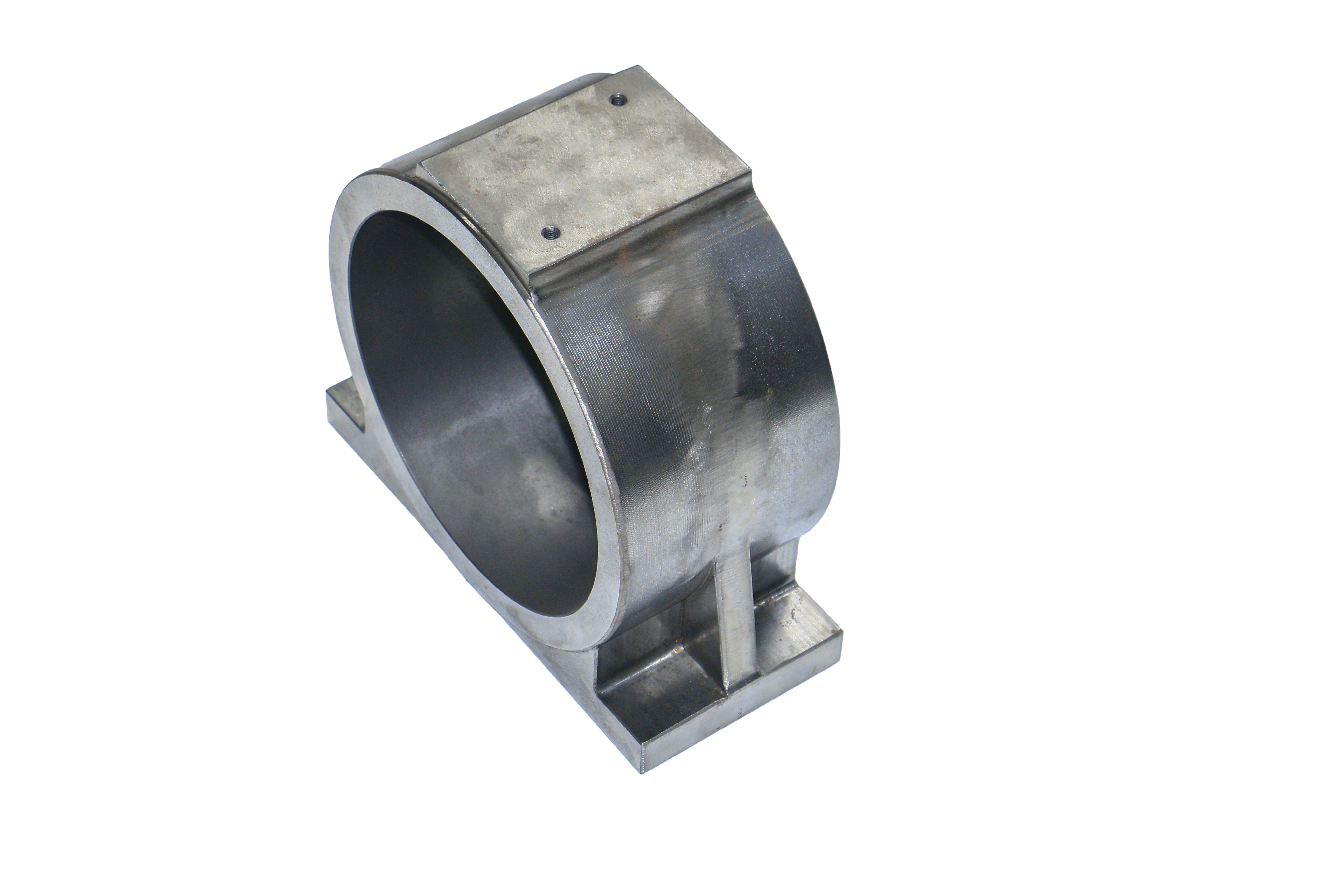

4-Axis CNC Tailstock MG-9710-Precision Support for Rotary Machining

Overview

Product Description:

4-Axis CNC Tailstock MG-9710 is a high-precision support component designed for rotary tables in multi-axis CNC machining. Engineered for stability, accuracy, and durability, this tailstock provides essential reinforcement for workpieces during machining, reducing deflection and ensuring superior precision. Ideal for industries requiring advanced rotational machining, MG-9710 enhances productivity and extends machine lifespan.

Key Features:

- High-Precision Alignment: Ensures accurate support for workpieces, reducing vibration and enhancing machining quality.

- Robust Construction: Built with high-strength materials for maximum durability and long-term reliability.

- Adjustable Design: Allows flexible height and positioning adjustments for different workpiece sizes.

- Heavy Load Capacity: Designed to support large and heavy workpieces in high-speed machining operations.

- Seamless CNC Integration: Compatible with a wide range of 4-axis rotary tables and CNC machines.

Applications:

- Aerospace Industry: Provides stability for precision machining of turbine components and aircraft parts.

- Automotive Manufacturing: Supports complex machining of engine parts, transmission components, and structural elements.

- Mold & Die Making: Ensures accuracy in the production of intricate molds and dies.

- General CNC Machining: Enhances machining efficiency and precision in multi-axis milling and turning applications.

With 4-Axis CNC Tailstock MG-9710, manufacturers can achieve higher accuracy, better surface finishes, and increased machining efficiency, making it a crucial component for high-performance CNC machining setups.